Properties, Advantages, & applications of cold-rolled steel in brief

The physical structures are made with fundamental objects & firm core elements. Construction & engineering requires many key features & different types of steel products are one of the major requirements. These steel products are classified into different types & the basic properties of steel are magnificently enhanced by processing through structured methods. The dynamic and innovative capabilities of these grade steel products make them sustainable & tough. One of the most renowned & utilized types of steel is cold-rolled steel. The specific functions of cold-rolled steel enable numerous applications useful for essential industries.

What is cold-rolled steel?

Cold rolling is a process in which metal is passed through rollers at temperatures below its re-crystallization temperatures. The cold-rolled process enhances the yield strength, toughness & strength of the metal. The hard microstructure is created in this process which prevents further slip. Cold-rolled sheets can be designed precisely; thus, desired microstructural accuracy can be obtained through cold-rolled methods. The material is first hot-rolled before processing.

Unlike Hot rolling, cold rolling has a fast forming speed, high output, and without damaging the coating. There is no thermal plastic compression during the forming process; still, slag-stress exists in the section that impacts the characteristics of steel. Cold-rolled sheets, plates & bars are durable & reliable.

Properties of Cold-rolled steel

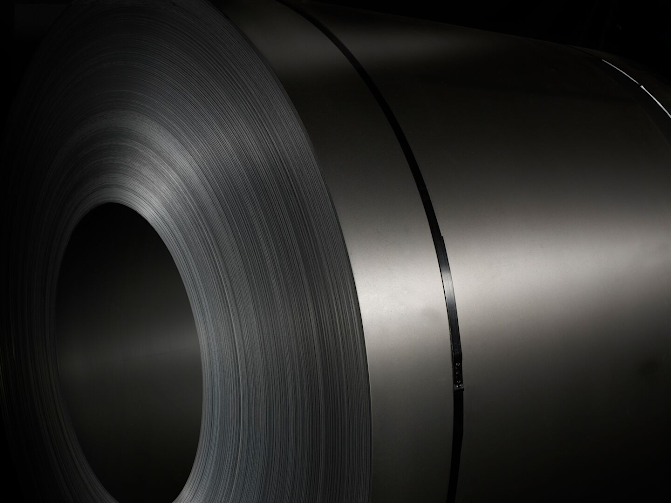

Cold-rolled steel's properties are enhanced due to the calculated process. Major mechanical properties like tensile strength, yield strength, workability, weld-ability, & metallurgical properties play a vital role in strengthening the core of structures. Cold-rolled steel is also ideal in industrial applications where aesthetic designs are required. This metal can be shaped into any particular shape & size and detailed minutely. Cold-rolled rod wires retain their shapes & offer excellent dimension accuracy. Cold-rolled steel coils have a smooth texture & fine finishing.

Advantages of cold-rolled steel

The key features of cold-rolled steel products include 20 percent greater strength than hot-rolled steel. These grade steels have super tight Dimensions & improved machinability due to fine processing. The manufacturing process of cold-rolled steel doesn't include expensive tools, and so it reduces the production & maintenance costs. The cold rolling process offers benefits like close tolerance up to 0.025 mm. Clean surface, excellent resistance & ability to withstand extreme conditions make cold-rolled steel one of the best types.

Applications of cold-rolled steel

The high strength, versatility & numerous remarkable properties of cold-rolled steel make it ideal for the machining industry, where the quality & grade of steel products determines the quality of the final product. Some of the other mainstream applications of cold-rolled steel are:

Construction & engineering industry

Home appliances

Furniture

Textile industry

Metal containers

Logistic sectors

Garage

Automotive industry

The fundamental functioning of cold-rolled steel is highly beneficial & reliable in multiple industries. As per the requirements of your project, you can check out the finest manufacturers of cold-rolled steel like JSW steel & gain more insights. They provide standard hot & cold-rolled steel products with a wide range of grades.

Comments

Post a Comment